ENDURANCE CARBIDE

BRIDGEPORT, MICHIGAN

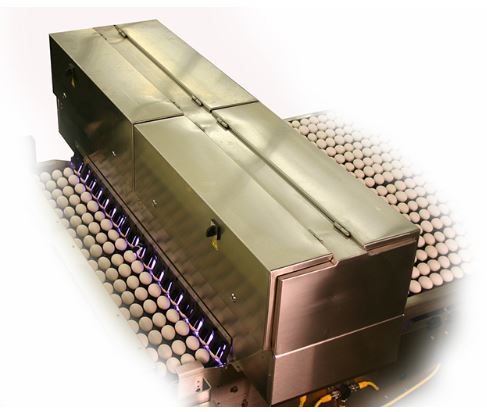

Precision Industrial Carbide Wear Parts since 1961

Outlast – Outperform

As a manufacturer of tungsten carbide precision wear parts, our name Endurance Carbide makes a lot of sense: carbide lasts a long time – much longer than steel.

Our company started in 1961, shortly after carbide’s initial growth in prominence following the late 1950s. Before then, steel had quite the monopoly throughout the World War II era.

Carbide is tremendously effective and lasts longer. You may pay a little more in short term, but it’s a cost-savings measure in the long term. The longer tool life not only eventually saves you money, but also increases production since you’ll have less machine downtime.

And carbide has only improved since it first arrived to the scene. When it first started getting used, there were only a limited amount carbide grades – ranging from c-2 through c-19. There are at least 5,000 different grades of tungsten carbide sold under more than 1,500 different trade names by more than 1,500 different companies.

Carbide’s certainly changed a lot since our company first started, and is growing more and more in use over steel. Mark Porath, Endurance Carbide’s General Manager, said to convenience a customer in switching from steel to carbide still takes some doing because they worry that it will bust. Many are still hesitant, but it is getting so much better. Steel can be very forgiving in that regard, but we’ve found once someone does make the change, they never return to steel.

Company Videos

Articles & News